DESCRIPTION OF BETA-CYCLODEXTRIN

Basic information

- Name: β-Cyclodextrin

- Short name: β-CD

- Quality standard: USP2021/EP9.6/ CP2020

- CAS No.: 7585-39-9

Product performance, features and basic applications

Performance and features:

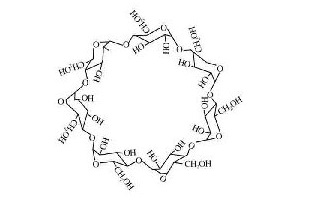

Betacyclodextrin (β-cyclodextrin, abbreviated as β-CD) is a ring formed cyclodextrin with glucosyltransferase acting on starch milk and connecting 7 glucose units via α-1.4 glycoside bond. It is made from tapioca starch imported from Thailand.

Betacyclodextrin (β-cyclodextrin, abbreviated as β-CD) is a ring formed cyclodextrin with glucosyltransferase acting on starch milk and connecting 7 glucose units via α-1.4 glycoside bond. It is made from tapioca starch imported from Thailand.

There is a cavity in the middle of the molecular structure of beta-cyclodextrin. The secondary alcoholic hydroxyl group of the molecular glucose bond is located outside the ring structure of the cavity, which is hydrophilic or polar, and the primary hydroxyl group is located in the ring structure of the cavity. Inside, it is hydrophobic (lipophilic) or non-polar. Due to the special nature of the two polarities of structures, a variety of smaller molecular compounds can be encapsulated in the cavity to form an inclusion complex. Industrial applications are to use the unique nature of cavity.

Application fields

β-cyclodextrin is a good excipient, flavoring agent, stabilizer, emulsifier, pservative and quality improver in industrial production. It is widely used in the fields of pharmaceutical industry, food industry and daily chemical industry to improve stability and quality of products.

1) Application in the pharmaceutical industry

* Increase stability of drugs

* Reduce irritation, toxicity, side effects of the drug and mask undesirable odor

* Increase solubility of drugs

2) Application in the food industry

* Stabilizers, slow release agents for spicy spices, flavors, flavors, and pigments

* Moisture-proof, moisturizing, anti-corrosion, deodorization, emulsification, extended shelf life

3) Application in daily chemical industry

* Reduce side effects, improve stability, and extend fragrance

3. Usage and dosage

1) Wet packing method

Example: Saturated solution method: The cyclodextrin product is heated and dissolved in water to ppare a saturated solution, and then the guest molecular compound is added, and the mixture is thoroughly stirred and mixed to ppare an inclusion complex.

2) Dry packing method

Example: Grinding method: Take cyclodextrin, add 2 to 5 times of water, then add guest molecular compound (if necessary, add appropriate amount of organic solvent), and grind and mix thoroughly in a mill to form a paste. One method is to be washed with water or a suitable solvent, and after drying, a stable inclusion complex is obtained. Second method is to be freeze-dried to form a powder, that is, a stable encapsulated complex is obtained.

Dosage:

The amount of cyclodextrin depends on the size and polarity of the molecular compound of the guest compound. The host molecule has a certain molar ratio to the inclusion of the guest molecule, and is generally about 1:1 to 2:1 or more. Because the inclusion process is affected by several factors (temperature, pssure, concentration, speed, guest molecular structure, etc.), the ratio is adjusted according to the effect of the inclusion and use during use, and a test decision is required.

Used as a improver for flour

1) Thickener. It has the following effects in food: (1) Enhance the protein adhesion in raw flour. (2) The starch particles are bonded to each other and dispersed to penetrate into the network structure of the protein. (3) Forming a dense dough with a smooth surface and luster. (4) Forming a stable dough colloid to pvent the leakage of soluble starch. (5) Strong water retention, so that the moisture is evenly kept in the dough to pvent drying. (6) Improve the ductility of the dough. (7) The oil and fat component in the raw material is stably dispersed in the dough.

2) As an electrolyte interacts with proteins, it changes the structure of the protein, enhances the viscoelasticity of the food, and improves the tissue.

3) Application examples: bread, cakes, noodles, macaroni, improve raw material utilization, improve taste and flavor. The dosage is 0.05%.

III. Packing, storage and shelf life

Packing: The packaging materials are in line with the national food and pharmaceutical packaging requirements. The inner packaging is PE bag, and the outer packaging is a seven-layer corrugated carton

Specification: 20kg/carton,25kg/bag.

Shelf life: Store in a cool dry place for 2 years.

Transportation: moisture, water, fire and pollution should be protected during transportation.

NEED HELP FOR YOUR FINANCIAL CONSULTING ?

Perspiciatis unde omnis iste natus error sit voluptatem accusantium doloremque laudantium, totam rem aperiam, eaque ipsa Neque.